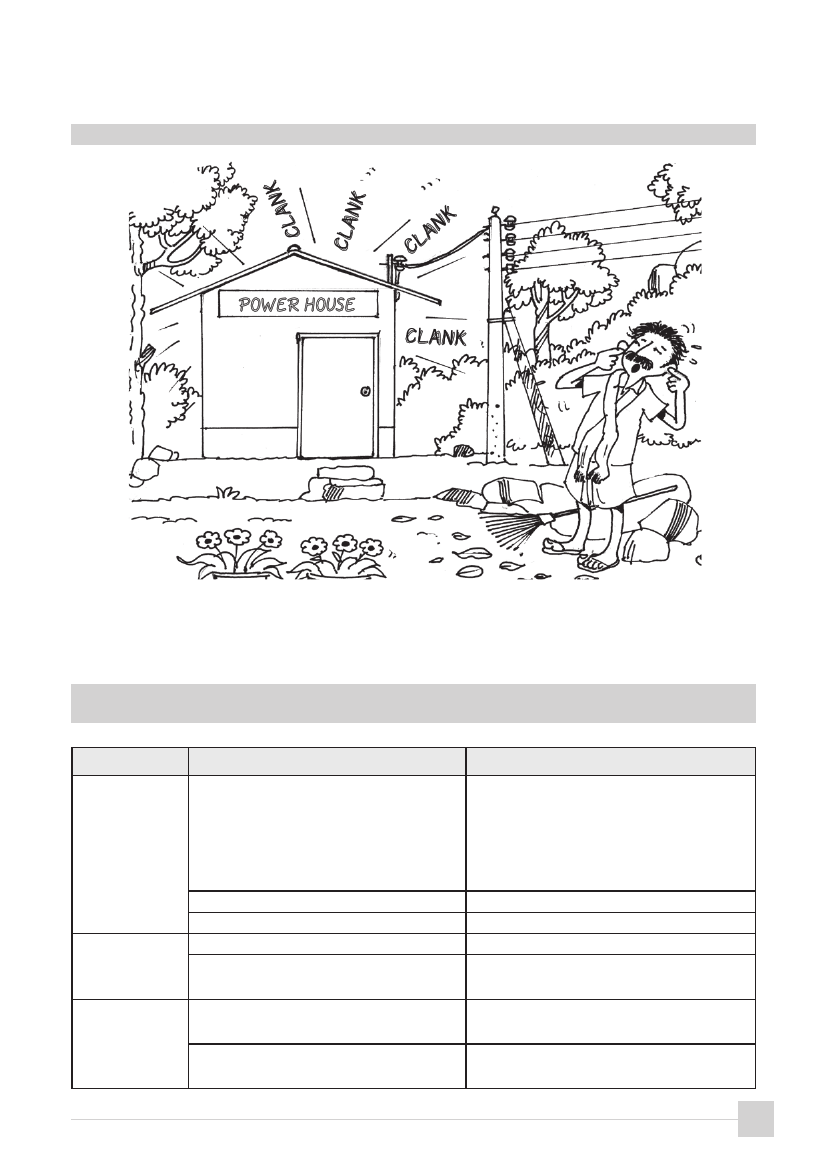

Noises can be generated due to the vibrations mentioned, something touching the rotating parts, or the

nozzles of the turbine being partially blocked. Identify the source of the noise and undertake adequate

repairs.

Unusual noise emitted from the turbine

POWER HOUSE

CLANK

CLANK

Some components such as generators, bearings, belts and pulleys get heated due to faulty conditions.

By being familiar with the working temperature, you can identify whether it is overheated or not. The

following table gives possible reasons for overheating.

Table 1 : Possible reasons for overheating

Item

Possible Reasons

Bearing housing No grease / too much grease

Generator

Belt & Pulley

Belt too tight / misalignment

Bearing is too tight (sleeve adaptor type)

Cooling fan is blocked

Electrical fault in the generator or control

system

Belts too loose

Grease is smeared on belt or pulley

Remedy

Apply grease as specified by the manufac-

turer. If this has not been specified by the

manufacturer, grease in intervals of 4,000

hrs. If there is excess grease, remove the

excess grease.

Adjust the tightness / alignment

Adjust the bearing sleeve

Remove the fan casing and clean

Please refer to the following paragraph under

electrical equipments

Tighten the belt. Do not use old and new

belts together.

Clean the pulley and belt and get rid of

grease

15